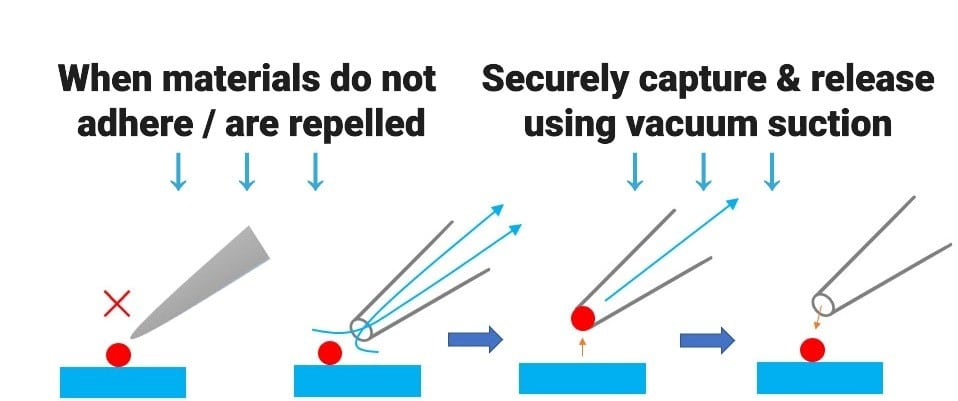

Are you having trouble picking up very small inorganics such as minerals, glass, or metal fragments?

When handling inorganics, they may be repelled or blown away by static electricity during pickup, or they may simply be too heavy to lift using conventional methods. To address this, MicroSupport proposes the Vaccum tweezers as a tool with their Axis Pro FC. This uses a technique in which a micro-nozzle applies vacuum suction can capture the target material securely.

Sampling Micro-solids by Vacuum Tweezers

A glass micro-nozzle is connected to a vacuum pump, and vacuum is applied continuously to hold the target material securely by suction.

Key Points of Vacuum Tweezers

- Observe and measure the target under a microscope to understand its condition (size, shape, etc.).

- Select a nozzle (pipette) that is slightly smaller than the size of the target material.

- Use the manipulator to bring the nozzle tip close to the target, switch the vacuum ON, and move closer until the material is fully attached.

- Once attached, keep the vacuum ON, quickly move to the drop-off location, then switch the vacuum OFF to release the material.

Micro-operation Supporting Equipment for Semiconductor Field

With the growing global demand for semiconductors, we have recently received an increasing number of inquiries and requests from customers involved in inorganic analysis. Here are some of the most frequently asked questions and their applications

| Issues You Want to Solve | Application Image |

|

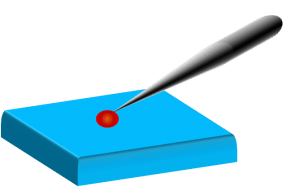

Sampling Foreign Micro-substances

|

|

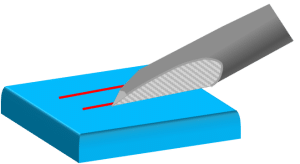

Pinpoint Marking

|

|

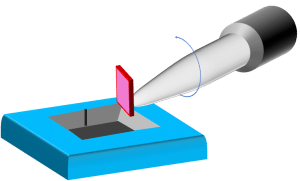

FIB-processed Lamella Lift-Out

|

|

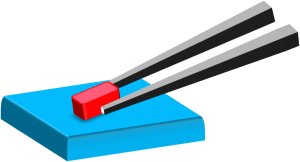

Micro-chip Holding / Suction

|